在线留言

About About

Product Product

SmartInnovation SmartInnovation

Case Case

Service Service

News News

Join us Join us

Contact Contact

400-1800-803

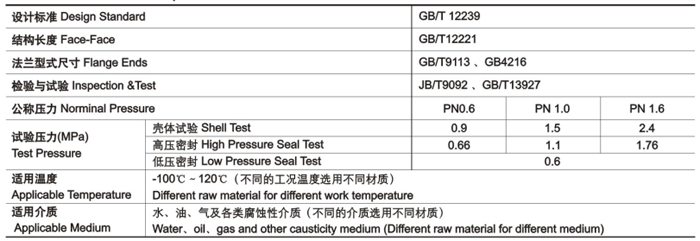

A diaphragm valve is a special type of shut-off valve. Its closure member is a diaphragm made of flexible material, which separates the valve body cavity from the bonnet cavity, protecting components above the diaphragm from medium corrosion. The valve body can be lined with materials such as enamel, rubber, and plastic as needed, offering strong corrosion resistance and good sealing performance. Actuation methods include manual, pneumatic, and electric, providing safe and reliable operation. It is widely used in industries such as petroleum, chemical, power, pharmaceutical, and environmental protection.

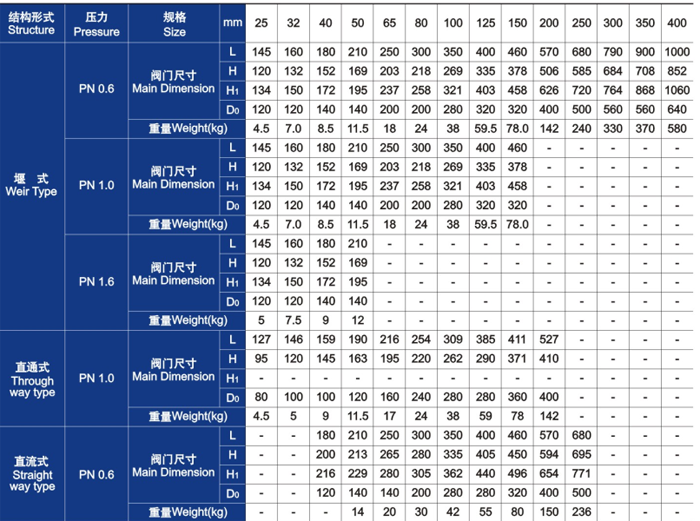

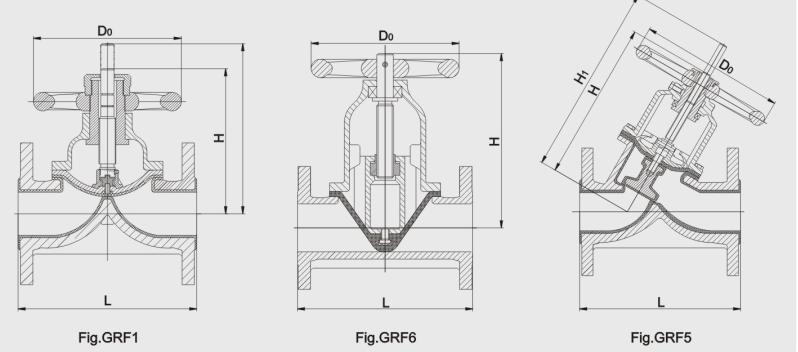

The weir-type diaphragm valve requires only a small operating force and short diaphragm stroke for opening and closing, resulting in minimal diaphragm flexure. This extends diaphragm life, reduces maintenance and downtime, lowers production costs, and makes it the most widely used type. When closed to approximately 2/3 of its open position, the weir-type diaphragm valve can also be used for flow control. However, to prevent sealing surfaces from corrosive media and cavitation damage in liquid media, flow control near the closed position should be avoided as much as possible.

Straight-Through and Y-Pattern Types The straight-through diaphragm valve has no weir, allowing fluid to flow straight through the valve cavity. This makes it particularly suitable for certain viscous fluids, slurries, and settling fluids. Compared to the weir-type, the diaphragm stroke is longer in the straight-through type. Consequently, this structure limits the range of synthetic rubber materials available for diaphragm selection.

在线留言