在线留言

About About

Product Product

SmartInnovation SmartInnovation

Case Case

Service Service

News News

Join us Join us

Contact Contact

400-1800-803

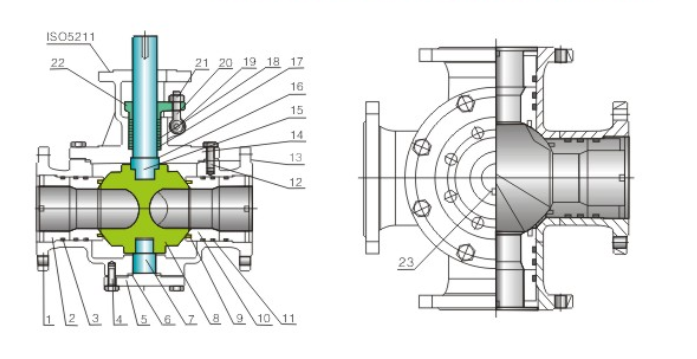

In power station systems, the four-way ball valve is referred to as a bidirectional water supply diverter valve (also known as an air flow direction switching valve in petrochemical systems). It is suitable for circulating systems handling liquids, gases, dust, slurries, and media containing solid particles. For example: forward and reverse cycle water supply systems for power plant unit coolers. Traditional process piping methods for achieving forward and reverse cooling water cycles occupy large space, have high costs, and involve cumbersome operation (requiring the operation of four valves for each switch): Valves 1 and 3 open and Valves 2 and 4 close for forward water supply; Valves 2 and 4 open and Valves 1 and 3 close for reverse water supply. Using a four-way ball valve to replace this process manifold and valve group simplifies the procedure, facilitates operation, reduces costs, improves controllability, and offers good synchronization.

1. Designed specifically for the forward/reverse water supply process in power system coolers, offering functional suitability and reliability;

2. Top-entry fixed ball with four-sided seat valve core structure provides good sealing performance, resistance to sand particle abrasion, and long service life;

3. Electric or pneumatic operation (can be switched to manual operation if necessary);

4. Facilitating control: Good information channels and operation interfaces between the control box and the valve, and with the host computer. Can achieve automatic switching between forward and reverse water supply at set time intervals as per process requirements.

Basic Design Standard: ANSI B16.34

Pressure-Temperature Rating: ANSI B16.34, DIN3356

Face-to-Face Dimensions: ASME B16.10

Connection Flange: ASME B16.5, DIN 2543-2551

Inspection & Testing: API598, DIN3230

在线留言